Nature comes at you fast. Step outside in Boulder, Colorado, and you’ll drown in the raging summer foliage. A couple of months ago, the trees were barren and brown grass lay dormant. Now, leaves sprout everywhere, and flowers are exploding into a rainbow of colors. The only place nearby where life blooms even faster is in any one of the small city’s 20 or so breweries. In the steel walls of a massive cultivation tank, nature’s mastery of scale is stepped up by several clips.

Humans have fermented yeast and bacteria for thousands of years, but within the last decade, the job description for domesticated microbes has expanded dramatically, turning them into factories for drugs and industrial chemicals. The scale of industrial fermentation is truly impressive. Scientists in white coats, masks, and goggles have to climb up ladders beside towering steel vats. Inside, massive impellers stir a fermentation broth as oxygen bubbles in to sustain hardworking microbes. Pumps thump, pressure valves hiss: how did this seemingly inhospitable setting become our best arena for cultivating life?

Large-scale industrial bioreactors are largely based on equipment developed for the chemical industry. They incorporate the engineering principles that account for concentration and temperature gradients, mixing speed and transport phenomena, reaction kinetics, and theoretical yield calculations. They do not account for one important detail — the complexity of life. We treat fermentation like a simple chemical equation, forgetting that inside each cell, there are hundreds of different reactions happening in parallel.

“The microorganism itself is a chemical factory,” says Dennis Vigil, a professor of chemical and biological engineering at Iowa State University. “But microbes are extremely sensitive to their microenvironment: factors like temperature, pH, or toxins.” Unlike a chemical process, microbes have a kind of memory — how they behave depends on where they have been and what kind of environment they experienced.

While engineers design bioreactors with freely circulating microbes in mind, the majority of microbes naturally form dense static networks called biofilms that mess up operations. And no matter how well you mix a reactor’s contents, you’ll never get the same conditions everywhere. The pressure at the bottom of a 500,000-liter fermenter can reach up to four atmospheres — comparable to what a scuba diver experiences at a depth of 100 feet and very different to conditions at the surface.

“It’s natural that we would re-use equipment we already have on hand, because where else are you going to start?” Vigil says. “But we desperately need innovation in process engineering and the equipment we use.”

Vigil is not the only one who thinks bioreactors need a makeover. BioMADE, a nonprofit public-private partnership, recently announced funding for projects to develop better bioreactor designs, with support from Schmidt Futures. The Department of Defense funds the organization, resolving to scale up U.S. biomanufacturing and help de-risk investment in relevant infrastructure.

“We can make a lot of different products in shake flasks. It’s a totally different problem to scale up a process like that for commercial viability. It can’t be just about engineering microorganisms; we also need innovation in process engineering and the equipment we use,” says Vigil, who received funding for one of the bioreactor innovation projects.

When researchers engineer microbes in the lab, they test their performance in the best possible conditions: ample space, ideal temperature and pressure, an abundance of nutrients, fresh oxygen on demand, and constant monitoring of vitals. But inside the bioreactor, those microbes endure high shear forces, overcrowding, and limited resources. Their job of making valuable products becomes much more difficult.

What if rather than expecting microbes to perform at their best in tanks borrowed from the chemical industry we built bioreactors with biology in mind? What if we worked with biology, rather than against it?

A Sticking Point

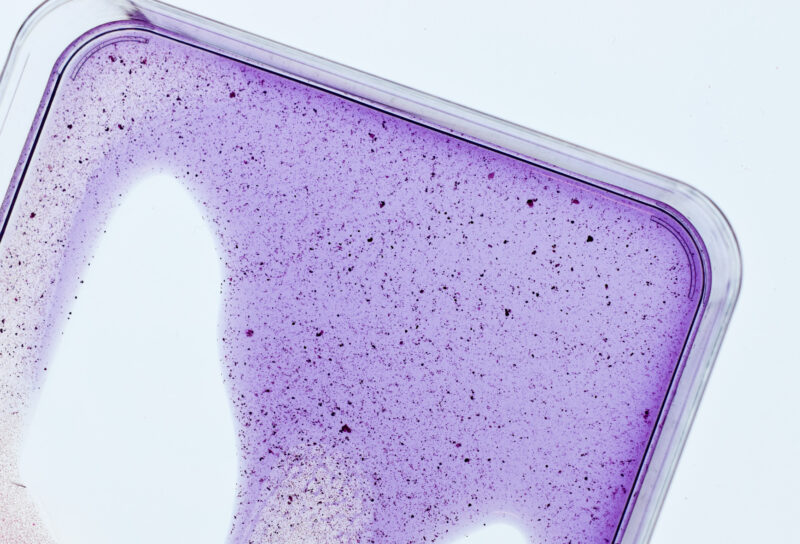

The current state of bioreactors strongly limits what microbes we can employ. Millions of microbial species are just too weird. Some grow too slowly. Some form long filaments that create a great texture for lab-grown meat but turn fermentation broth to unmanageable foam. Some are incredibly useful like the yogurt-making lactic acid in bacteria, but they form biofilms that clog tubing and impede the transfer of oxygen and nutrients.

Biomanufacturers rarely consider using these problematic microbes. Instead they rely on the docile E. coli and baker’s yeast (Saccharomyces cerevisiae) that we have been growing for ages in large fermentation tanks. But many so-called non-model organisms can do things that E. coli can’t. We are missing out on these unique abilities by not using them.

Some startups, like MicroByre, have been working to domesticate those reluctant, recalcitrant, and rebellious microbes by adapting them for use in the lab and creating genetic tools to manipulate them. However, adding those wild microbes to our fleet of biotech producers requires more than just learning how to engineer them. “A lot of overlooked microbes could be amazing for biotechnology,” says Liz Onderko, the co-founder and CEO of Capra Biosciences, “but they just don’t have the right reactor to perform in.”

Capra Biosciences harnesses the superpowers of a biofilm-forming organism Marinobacter atlanticus to make fat-soluble products like retinol which is used in anti-aging face creams, and high-end industrial lubricants for electric car engines. “I worked with biofilm-forming organisms during my postdoc, so I have a lot of affection for them,” Onderko says. Normally, biofilms are bad news in large-scale fermentation. But Onderko suggests that we should flip that perspective.

A biofilm’s living wall protects its cells from toxic solvents, contaminants, or antimicrobial agents. The close-knit community relays chemical signals to each other to mount coordinated responses to changes in their environment. They grow slower but live longer and do not need to be constantly replenished with fresh starter culture as the live-fast-die-young E. coli does. “You’ve got to admire their robustness,” Onderko says.

Biofilm-forming microbes are rare in biotech’s vats but much more common in nature. About 80% of all microbes in the environment form biofilms. “So, it’s really not the exception,” Onderko says. “It’s how most organisms prefer to be.”

Capra developed bioreactors to take advantage of this property. Since the biofilm can stay alive and healthy for a long time, they designed a continuous fermentation process so that they can extract the product without disturbing the organisms. They also added packing materials to the hollow tube of the reactor to provide ample surface area for the biofilm to grow on.

This continuous bioreactor uses much less water, energy, and nutrients and does not need to be sterilized after each run. Plus, it’s modular: each reactor is 35 liters in volume and can be connected to others in parallel to generate whatever volume of product needed to make the process commercially feasible. Scaling “horizontally” this way beats doing so “vertically” in one giant tank, according to Onderko. “Nature does not grow one giant leaf,” she says. “It grows a whole tree with hundreds of thousands of them.”

We treat fermentation like a simple chemical equation, forgetting that inside each cell, there are hundreds of different reactions happening in parallel.

Going Big

Just like the microbes in their reactor, Capra has been doubling almost every year. They started as two co-founders sharing one lab bench and now have six full-time employees in their headquarters in northern Virginia. They currently operate in a 1,000-square-foot lab space while building a new facility set to open in 2025 using funds from BioMADE’s project call. The new plant is expected to help Capra scale production from a gram-scale to a metric ton per year.

“One of the reasons why we exist is to help companies through the biotech valley of death,” says Penny Norquist, Senior Program Manager at BioMADE. Capra is one of the five recipients of the bioreactor innovation project funding. In return for the funding, each recipient will contribute back to the BioMADE ecosystem by sharing the knowledge they have gained: “If one of them has already done the work to come up with a new bioreactor design and to figure out why it works with a particular organism or product type, perhaps someone else could try it for a different application.”

Each of the projects is solving a different piece of the scaleup puzzle. For example, Geno, a San Diego sustainable materials company that brews up bio-based molecules to make carpet fibers and nylon yoga pants, is modeling and mimicking bioreactor pressure and temperature gradients to predict scaleup performance. Amyris, an Emeryville biotech, is working on bioreactor design modifications to minimize the impact of growth-inhibiting fermentation products, such as the antimalarial drug precursors. Vigil’s Iowa State lab has proposed a bioreactor mixing technology that combines fermentation with extraction and separation steps. And another team from Iowa State University is working in collaboration with Novozymes to develop sensors and machine-learning models to improve bioreactor control.

The enormous variety of microbes, processes, and potential synthetic biology products requires that engineers come up with creative fermentation solutions that match that same diversity. They must think outside the tank and not be constrained by the existing technologies and equipment we have on hand.

“Working with biology requires imagination,” Onderko says. “Instead of relying on what was left over, we have the ability to build the exact things we want from the ground up.”